extrusion temperature profile

PP - Polypropylene Extruder. Billet temperature at the entry of the extrusion press is a critical process control parameter.

Extrusion Ratio An Overview Sciencedirect Topics

Clumping or balling-up in the feed throat can be avoided by keeping the feed throat cool.

. Plastics extrusion is a continuous high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. A high billet temperature limits the maximum speed of the extrusion press and can result in. As you know PVC has a melting temperature starting around 160 C.

Ad Custom Profile Extrusions for Industrial Applications. Make sure the die and head can take the expected pressures too but maximum pressure is at the screw tip. Raising the temperature of the die prior to purging may help to remove excessive build up.

They can also be co-extruded with other materials to yield a part with both rigid and soft components. Feed Throat Zone 1 Zone 2 Vent Zone Zone. Know where you are measuring what to expect and.

Barrier Screw 25 - 30 LD Compression Ratio. The effects of repetitive extrusion cycles at different die temperatures in a single screw extruder were investigated by thermal analysis degree of crystallinity χc heat of fusion ΔHm. If the rate seems too low try raising the set points on.

Single Screw Extruder with vacuum grooved feeding section Screw Design. Setting the center and front zones. A cold die will restrict flow where as a too-hot die will affect dimensions.

More often than not extrusion operators. The goal is to have the front zone at the same. Therefore some specialists may suggest carrying out extrusion above this temperature and as far as 218 C.

The article discusses the. Single Screw with vacuum grooved feeding section Screw Design. The extruder feed throat is.

But they can be optimized to reduce. Womer Resin Type Melt Index Density Melt Temp Target - ºF Z-N LLDPE 10 0918 400 to 430. Still sick but not ER-sick.

The pressure inside the extruder barrel during the extrusion process is high. Our TPE compounds are easily extruded into single and complex profiles. Sure enough a few spoonfuls of cold yogurt later it was down to 1002.

To achieve melt uniformity these are both set at the target melt temperature 485 F 250 C. Extrusion processes using a barrier-type screw for maximum output and performance need certain finer adjustments of barrel-temperature zone profiles. If the temperatures on the first few zones are set too low you will sometimes see small gels or unmelted particles in the extrudate.

Custom Profiles Sheets Compounds Quick Turns Difficult Specs. PE-HD - High-density polyethylene Extruder. Surface temperatures will be less until the extrudate is being cooled.

Ad Injection Molded Items And Plastic ExtrusionsSince 1985. Barrels for most extruders are designed to withstand operating pressures up to 10000 psi or. Ad Custom Profile Extrusions for Industrial Applications.

The die temperature will also influence output and will have an effect on the dimensions of the extrudate. This process starts by feeding plastic material. This is because that if the length of the belt from increasing its perimeter.

Another Technique for Controlling Melt Temperature Flight widths are almost always designed at 10 of the screw diameter. Suggested temperature profile for extruding. Ad New Source Offers The Largest In-Stock Inventory Of Raw Aerospace Metals.

The temperature of the aluminum profile at the outlet of the matrix increases with the perimeter of the girdle matrix. Higher viscosity resin lower MFI requires higher processing and melt temperatures. Normal operating pressures generally range between 1000 and 5000.

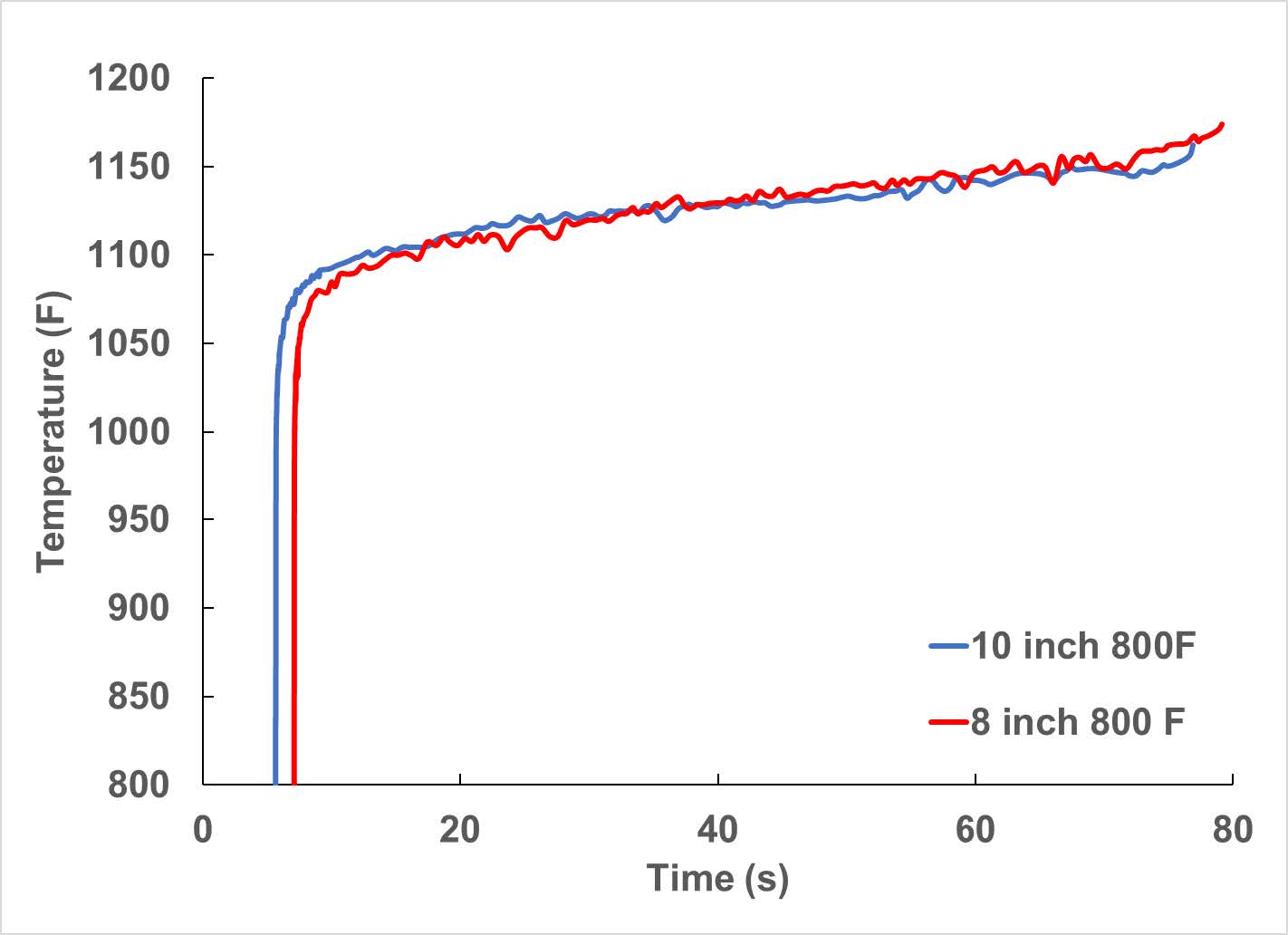

The hump back temperature profile By Timothy W. Lesson learned and applied to extrusion. Barrels for most extruders are designed to withstand operating pressures up to 10000 psi or 700 bar.

Guidelines for an acceptable temperature profile are given in Table 2215. Large Inventory of Raw Materials Domestic Dfars Compliant Custom Solutions. Barrier Screw 25-30 LD Compression Ratio.

Custom Profiles Sheets Compounds Quick Turns Difficult Specs. Suggested extrusion temperature limits Average extrusion temperatures Co-Extruder- Acrylic. A Du Pont nylon extrusion study noted that exit-melt-pressure fluctuations were seven times more extreme after the temperature of the two rear zones was dropped 50 deg F.

All commercially responsible extruders can take 3000 psi easily. ROLL Top Middle Bottom Fourth Fifth TEMPERATURE 99 110 107 88 66 EXTRUDER PLASTICIZING CAPACITY Line. Extrusion may be defined as a process for making a product an extrudate by forcing a material through an orifice or die to form a shape or alternatively the production of finished or semi.

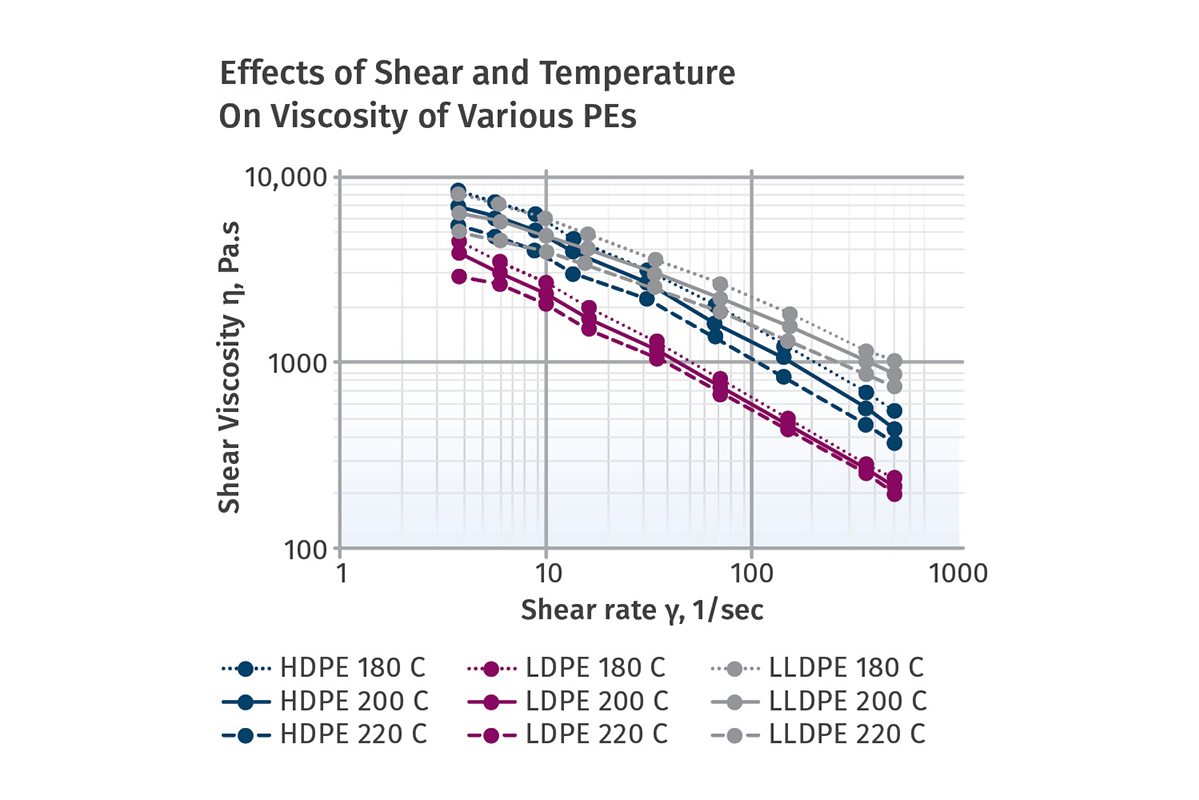

Understanding Viscosity In Extrusion Plastics Technology

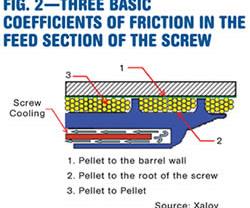

The Role Of Screw Design In Efficient Extrusion Of Medical Devices Plastics Technology

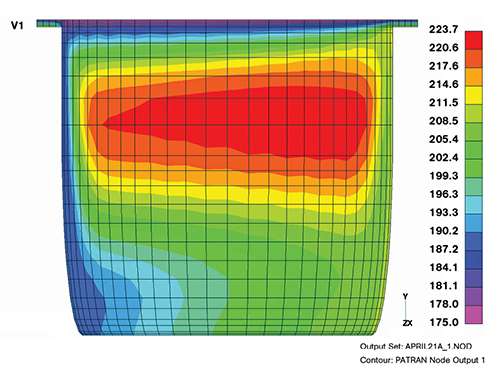

Barrel Temperature Profiles In C Download Scientific Diagram

Extruder Barrel Temperature Settings Temperature Settings Set Download Table

Extruder Barrel Temperature Settings Temperature Settings Set Download Table

Why Barrel Temperatures Have A Small Effect On Melt Temperature Plastics Technology

What Is Extrusion Plastic Extrusion Process Elastron Tpe

Article Extrusion Productivity Part I Billet Geometry Light Metal Age Magazine

Optimize Barrel Temperatures For Barrier Screws Plastics Technology

Extruder Barrel Temperature Settings Download Table

Example Of A Temperature Profile Of Plastic Extrusion Download Scientific Diagram

Schematic Illustration Of The Extrusion Line And The Temperature Of The Download Scientific Diagram

Comments

Post a Comment